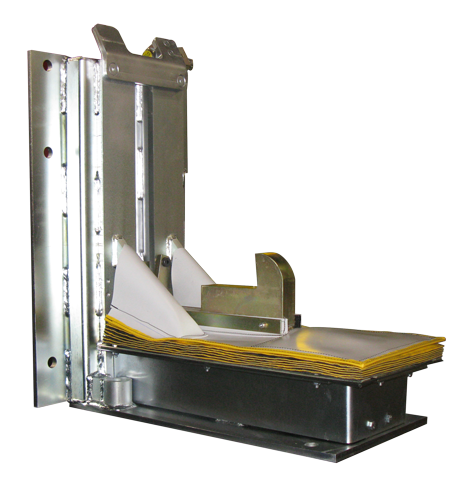

The TPR UniLock™ is the only trailer-postioned vehicle restraint that can automatically remove "RIG Wedge" pressure. RIG Wedge is caused when the trailer is pushed forward during loading/unloading and the trailer's Rear Impact Guard (RIG) applies so much pressure to the restraint's hook that the truck driver must reverse the trailer in order to release the restraint. The UniLock has an advanced cam design that first rotates the hook away from the RIG to remove the pressure, and then rotates down to a stored position.

The UniLock vehicle restraint also has an internal safety mechanism that locks the restraint's hook in place when pressure is applied, maintaining a secure engagement. This makes it universally effective on any obstructed Rear Impact Guard (RIG), including intermodal trailers with cover plates that prevent the restraint's hook from latching on top of the RIG.

The UniLock is designed to withstand a pulling force in excess of 32,000 lbs, and has a service range of 4” to 10” horizontally from the face of the dock bumpers and 9” to 30” vertically above drive approach. The integral motor, gear and brake assembly is specifically designed for the UniLock. The UniLock vehicle restraint is highly adaptable to new or existing loading docks.

The McGuire TPR® truck positioned vehicle restraint is designed to automatically position itself and secure a trailer’s rear impact guard (RIG) to reduce the likelihood of premature trailer separation during the loading/ unloading process.

The TPR® is designed to withstand a pulling force in excess of 32,000 lbs, and has a service range of 4” to 10” horizontally from the face of the dock bumpers and 9” to 30” vertically above drive approach. The integral motor, gear and brake assembly is specifically designed for the TPR®. The TPR® vehicle restraint is highly adaptable to new or existing loading docks.

The Hold-Tite® automatic vehicle restraint has push button activation with PLC solid state controls (115V/1PH) and a low profile, non-impact design for wall or driveway mount. Equipped with true positive hydraulic restraining force it virtually eliminates “trailer creep”, a major cause of incidents at the loading dock. It comes standard with auto restore and an amber caution light indicator if a trailer has no RIG (rear impact guard) or a badly damaged RIG. Keyed override for interlock condition and automatic light sequencing to indicate RIG or no RIG are some of the outstanding safety features.

The Hold-Tite® automatic vehicle restrain is built to last with full two (2) year base warranty on structural, hydraulic and electrical components and an additional three (3) years on structural. It also meets all current NHTSA regulations.

The Stop-Tite® AAL (automatic operation, automatic lights) vehicle restraint has push button activation (115V/1PH) with a unique dual locking restraint arm to minimize “trailer creep.” It has a low profile, non-impact design for wall or driveway mount. The remote power pack allows choice of mounting location. It can be mounted next to restraint, on the outside wall away from backing trailer, inside a leveler pit or positioned inside the building for ease of service. An override selector switch, audible alarm if no RIG, automatic light sequencing of the red/green inside/outside lights and available interlock terminals are all designed with safety in mind.

The Stop-Tite® AAL comes with a protective debris guard and an industrial grade powder coat finish. It features a full one (1) year base warranty on all structural, hydraulic and electrical components. It also meets all current NHTSA regulations.

The Stop-Tite® M, MML & MAL are all manually activated vehicle restraints via an operate handle. They all have a unique dual locking restraint arm that minimizes “trailer creep” for safety. These manually operated restraints all have a low profile non-impact design for wall and driveway mount. All three (3) types have a protective debris guard and an industrial grade powder coat finish.

The M version is manual operation and signs only. The MML version is manual operation and a manually operated communication system changed via a selector switch on an internal control panel that sequences the red/green inside/outside lights. The MAL version comes equipped with switching that will automatically sequence the inside/outside red/green lights. All three (3) versions feature a full one (1) year base warranty on all structural, hydraulic and electrical components. They also meet all current NHTSA regulations.